Welding Calculator

The welding calculator helps you in determining the strength of weld joints. Welding has been one of the majorly used joining and fabrication processes when it is challenging to use casting or forging or bolted joining methods or to permanently join pieces of material together. Our bolt circle calculator and bolt torque calculator gives more information on bolted joints.

Apart from welding, one can also use bolts, riveting, fastening, soldering, among many others, depending on the requirement. The joints are chosen based on the mechanical or thermal load an object should take under operating conditions.

This calculator covers the weld strength calculation for different types of welding joints. Read on to understand what is a fillet weld or a butt joint and their strength calculations.

Types of welding joints

Welding is the process of joining two pieces of materials utilizing heat and filler material. The use of filler material is not used in some types of welding processes. Some types of welding are:

- Arc welding

- Forge welding

- Inert gas welding

- Friction stir welding

- Electron beam welding

- Laser welding

- Spot/Seam welding

The most common feature among all the above types is the utilization of heat to permanently fuse the materials. The energy source of the heat is often a significant factor in the categorization of modern welding processes. These pieces of materials are joined in different arrangements. The 5 basic weld joints based on configuration are:

- Lap joint;

- Butt joint;

- T joint;

- Corner joint; and

- Edge joint.

The basic weld joints are used to build frames and load-bearing structures. Based on the alignment of pieces, the joint is either fillet weld, butt weld, or plug weld. When the pieces are aligned perpendicularly, the joint is known as fillet weld, whereas when the pieces are laid end to end, a butt weld is performed to join them together. This calculator covers lap and butt joints.

Weld strength calculation

The lap joints can either be single transverse, i.e., single weld line, double transverse, parallel, or combination of these welds. Similarly, the butt joints are either single or double-sided. The strength of the weld joint depends on either tensile or shear stress, or a combination of both. The direction of the weld joints decides the design stress (see stress calculator for more) acting on them. Let's consider lap joint welding first. A lap joint is about joining the pieces after overlapping them, welding along the edge.

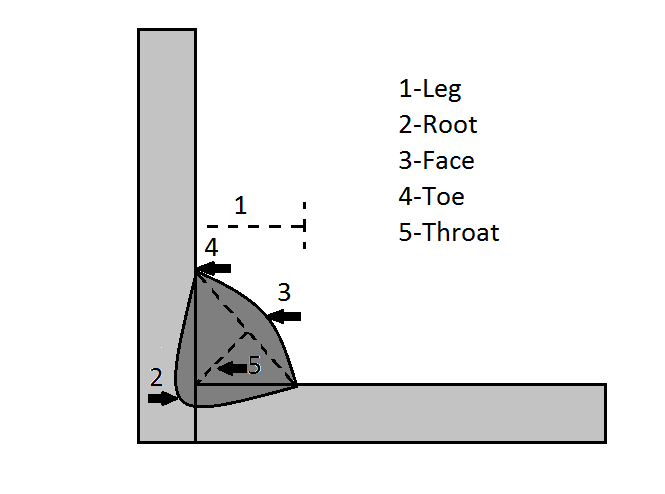

Fillet weld: A single transverse fillet weld considers the maximum permissible tensile stress of the material. The figure below contains the different parts of a fillet weld. Consider two pieces of length l joined together by a single fillet weld, the strength of the weld joint P is given by:

The throat area, A, is the product of throat thickness t and length of weld l. The throat thickness t is a function of the fillet weld size, which is equal to the thickness of the plate. Therefore, the strength of the weld formula for a single fillet weld is:

where is the maximum allowable stress and s is the fillet weld size. Similarly, the weld strength for a double fillet weld joint is:

When the weld line is parallel to the load direction, the joint is designed based on the maximum allowable shear stress, τ. The strength of a double parallel weld joint is:

Utilizing the combination of transverse and parallel welds, one can estimate the strength of a U-shaped joint. Such that there are two parallel welds, having length, and a transverse weld, . The strength of the joint is the sum of the strength of three joints.

Here, the total length of the weld joint is adjusted for the seam by adding 12.5 mm to it. Therefore, the total length of the joint is

Butt weld:

A butt joint is performed to join to pieces in an end-to-end alignment. These joints are designed for tension or compression loads. A butt joint could either fully penetrative from one side, i.e., as equal to the thickness of plates or double-sided with each side having throat thicknesses and . The weld strength formula for single butt joint welding is:

where l is the length of the weld joint. Similarly, the strength of double butt joint welding is:

The welding calculator utilizes the above set of weld strength formulae to determine their strength.

How to calculate weld strength?

To calculate weld strength:

- Select the type of joint from the list of weld types, say, transverse weld (double) or double fillet weld.

- Enter the length of weld,

l. - Fill in the size of weld,

s. - Insert the maximum permissible tensile stress .

- The welding calculator will return the weld strength,

Pof the joint.

Example of using the welding calculator.

Estimate the strength of a single transverse fillet weld joint consisting of two plates having thickness 5 mm and length 100 mm. Take the tensile stress as 70 MPa.

- Select the type of joint from the list of weld types as transverse weld (single).

- Enter the length of the weld,

l = 100 mm. - Fill in the size of weld,

s = 5 mm. - Insert the maximum permissible tensile stress MPa.

- Using the fillet weld size calculation formula:

What is a butt joint?

When two pieces of material are aligned end to end and joined together, it is known as the butt joint.

What is fillet weld?

A fillet weld is defined as the joint when two pieces are aligned perpendicularly and weld together.

How to calculate length of weld for a lap joint welding?

To estimate the weld strength:

- Multiply the size of weld and weld strength.

- Divide the maximum permissible tensile stress by the above product.

- Multiply the resultant by 0.707 to obtain the length of the weld joint.

How do I differentiate between a butt weld and lap weld?

A butt weld is performed when the plates are to be joined end to end, whereas a lap weld is used in case of joining overlapping plates.